Specification

| Type | TP-75 | TP-77 | TP-90 | TP-92 | TP-107 | TP-130 |

|---|---|---|---|---|---|---|

| Screw Dia | Φ75 | Φ77 | Φ90 | Φ92 | Φ107 | Φ130 |

| L/D | 25 | 28 | 25 | 28 | 25 | 25 |

| Drive Power | 30HP | 40HP | 60HP | 75HP | 100HP | 125/150HP |

| Screw RPM | 42 | 42 | 42 | 42 | 35 | 35 |

| Barrel Heater | 27kw | 35kw | 38kw | 45kw | 45kw | 70kw |

| Total Power | 62kw | 70kw | 90kw | 120kw | 140kw | 190kw |

| Output | 150-250kg/hr | 200-300kg/hr | 300-450kg/hr | 350-500kg/hr | 450-650kg/hr | 900-1100kg/hr |

Features

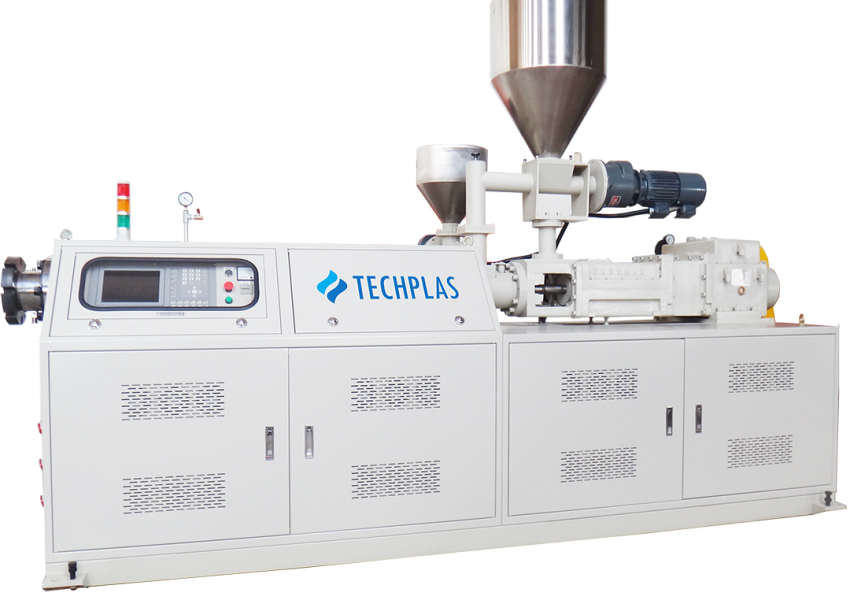

Parallel Counter-rotating Twin screw extruder is one of our best-selling machinery.

- Low power high performance output

- Outstanding melt homogeneity

- Maintenance-free, closed screw temperature control system

- Wide processing range thanks to metering and stuffing device

- Low wear thanks to low screw speed

- Gentle plasticing thanks to longer screw and barrel

- Well organized distribution of circuit

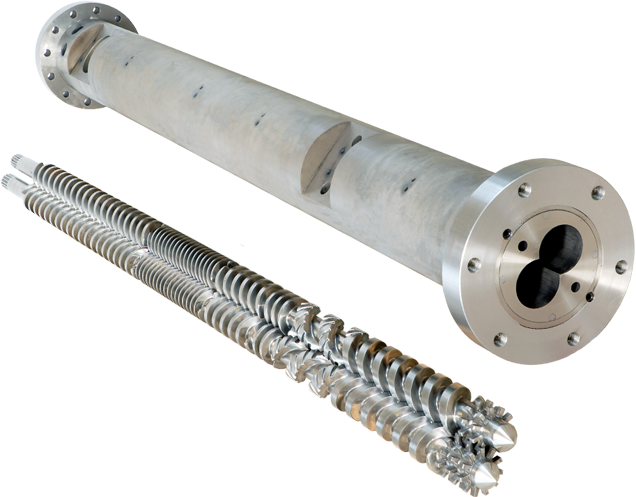

Twin Screw & Barrel

- Made of SACM645 material with heat and nitride treatment, high resistance to corrosion and attrition

- Unique design of thread process improves the efficiency of plasticization

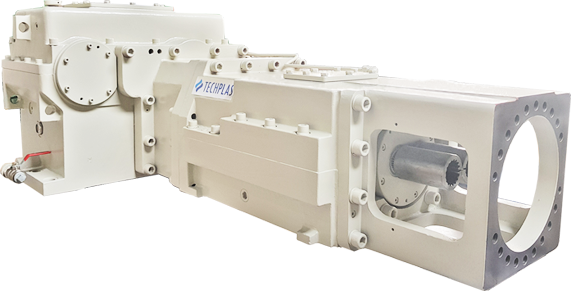

Precise Extruder Gearbox

- Compact design with high ratings of using high strength, cased-hardened steels

- Excellent output performance by using helical gear unit, reducing the forces of screw back pressure and operation noise

- Maximum operation reliability

- Enforced oil lubrication system keeps machine running smoothly

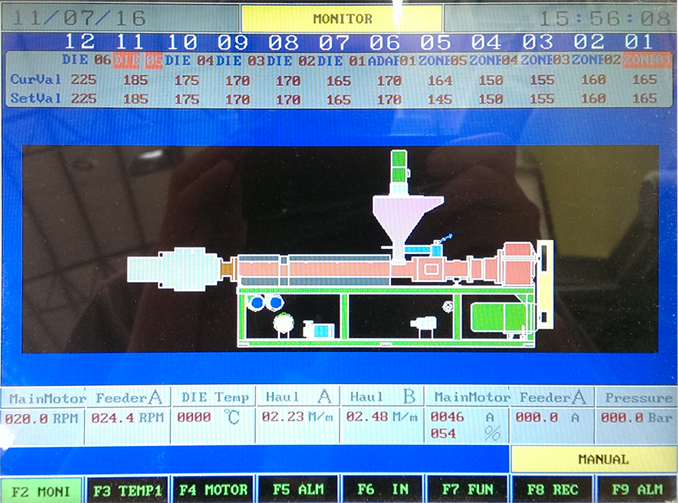

PC Base Control

M Series Machine Controller

- Motor interlock function

- 12 Zone PID temperature control (optional 24 zones) oil cooling, or blower cooling control

- PLC ladder logic program

- Alarm record function

Send your Inquiries

If you have questions, need quotations, or want to place an order, you are welcome to do so with this form.