Specifiaction

| Model | Raw Material | Suitable Pipe Dia | Production Capacity |

|---|---|---|---|

| TP-75-RP-S | PVC Compounding / Pellets | 60-160mm | 120-250 kg/hr |

| TP-90-RP-S | PVC Compounding / Pellets | 90-200mm | 300-400 kg/hr |

| TP-92-RP-S | PVC Compounding / Pellets | 160-315mm | 350-500 kg/hr |

| TP-130-RP-S | PVC Compounding / Pellets | 400-630mm | 800-1000kg/hr |

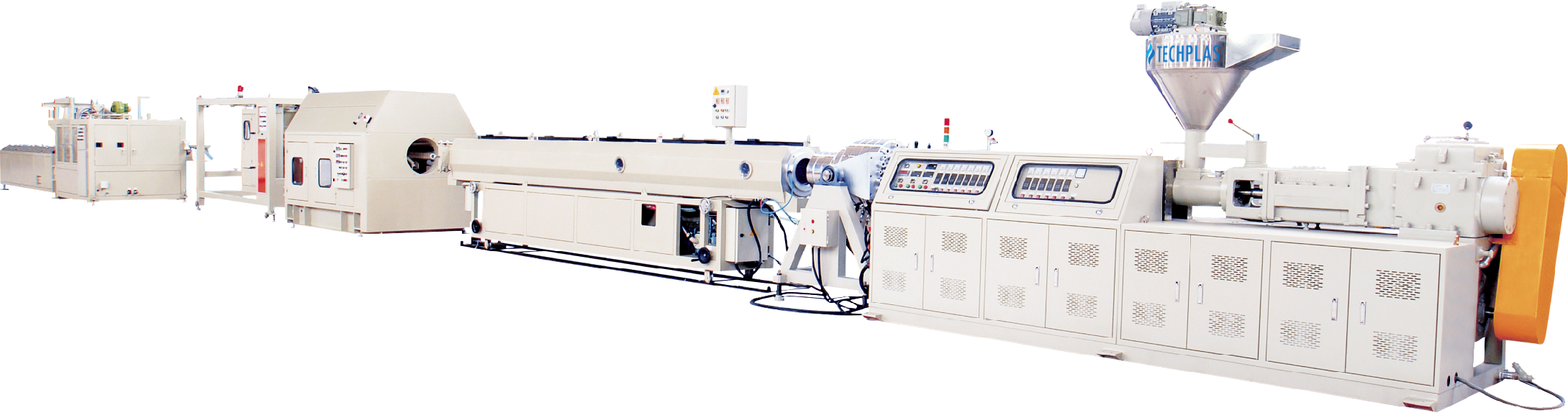

This line includes:

- Twin Screw Extruder

- Pipe Die Head

- Vacuum & Water Spray Cooling Tank

- Water Cooling Tank (Optional)

- Haul-off Unit

- Cutting Unit

- Automatic Belling Machine (Optional)

General Information

Equipped with A/C inverter.

The parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruder by increasing in the drive torques and unique design for better plasticization.

Equipped with A/C inverter

We offer two pads, three pads, four pads, six pads, or eight pads type haul-off machine for various pipe size range

Upstroke saws or planetary saws for various pipe sizes range, can be applied for making non-chamfered pipe or chamfer pipe.

It is additionally applied with length measuring limited and thickness increasing device.

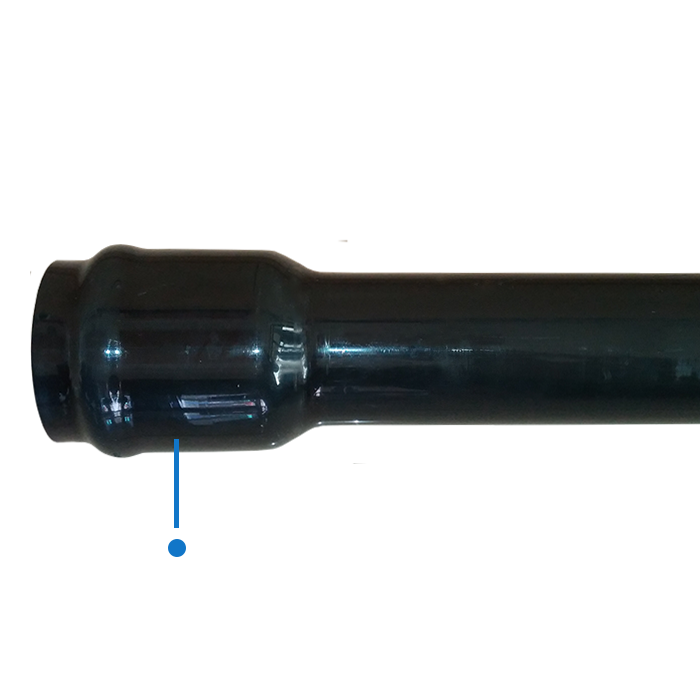

Type: solvent weld joint (U type) & spigot type gasket (rubber ring type, R type) belling or solvent weld joint (U type) belling only

Cooling function: Air cooling and water cooling

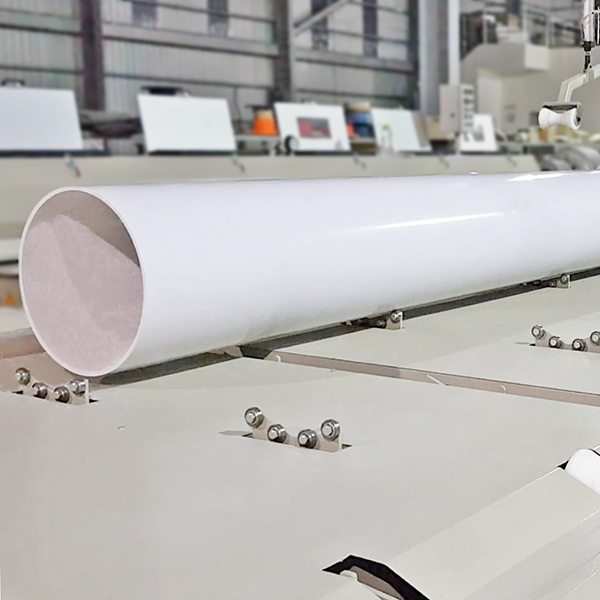

Final Products

- Drinking Water Pipes

- Pipes for Architecture

- Pipes for Well Drilling

Special R type belling for Japan clients. Making pipe seismic shockproof

Parallel Counter-Rotating PVC Twin Screw Extruder

Wider processing range of different formula

You can easily try out your best formula

PVC Extruder equipped high quality and longer twin screw, achieving outstanding melt homogeneity and highest output.

Send your Inquiries

If you have questions, need quotations, or want to place an order, you are welcome to do so with this form.